How Advanced Vision Technologies Are Reshaping the Global Surface Inspection Market

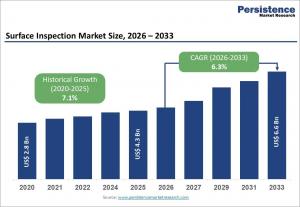

The global Surface Inspection market is expected to reach US$4.3 billion by 2026 and US$6.6 billion by 2033, growing at a CAGR of 6.3% from 2026 to 2033

BRENTFORD, ENGLAND, UNITED KINGDOM, January 26, 2026 /EINPresswire.com/ -- The surface inspection market plays a vital role in modern manufacturing by enabling precise detection of defects and quality variations using advanced optical systems, machine vision, and AI. These solutions help industries such as automotive, aerospace, electronics, and semiconductors improve product quality, reduce waste, and meet strict regulatory standards.

The global surface inspection market is projected to grow from US$ 4.3 billion in 2026 to US$ 6.6 billion by 2033, registering a CAGR of 6.3%. Growth is driven by rising automation, increasing labor costs, and the need to manage complex manufacturing processes, as automated inspection systems can improve production yields by 10–20% compared to manual methods.

3D surface inspection technology leads the market with nearly 52% share, due to its ability to detect complex and micro-level defects. North America dominates geographically, holding 43–45% market share, supported by advanced manufacturing capabilities, strict quality regulations, and strong semiconductor investments under initiatives like the U.S. Chips Act.

𝐆𝐞𝐭 𝐚 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐁𝐫𝐨𝐜𝐡𝐮𝐫𝐞 𝐨𝐟 𝐭𝐡𝐞 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.persistencemarketresearch.com/samples/33512

Surface Inspection Market Size, Statistics, and Growth Dynamics

Surface inspection systems are now essential in modern manufacturing as industries move toward zero-defect production. Inline deployment helps reduce downtime, enable real-time corrections, and lower rework and recall costs.

AI-driven inspection enables sub-pixel defect detection with 97–99% accuracy while cutting false positives by 60–70%, making it vital for safety-critical sectors like aerospace and automotive.

Asia Pacific leads growth with a 10.5–11.2% CAGR through 2032, driven by China’s industrial expansion, electronics manufacturing growth, and Industry 4.0 adoption.

Market Segmentation Analysis

The surface inspection market is segmented based on technology type, system configuration, application, and end-user industry. By technology, the market includes 2D vision systems, 3D surface inspection systems, and AI-based inspection solutions. Among these, 3D surface inspection systems dominate due to their ability to detect surface topology variations, scratches, dents, and dimensional inconsistencies that are difficult to identify using traditional 2D imaging.

From an end-user perspective, the market spans automotive, electronics and semiconductors, aerospace and defense, metals and materials, food and packaging, and pharmaceuticals. The electronics and semiconductor segment is a major contributor, driven by the need for defect-free wafers, printed circuit boards, and microelectronic components. As chip geometries continue to shrink, the tolerance for defects becomes increasingly narrow, making advanced surface inspection systems indispensable.

𝐃𝐨 𝐘𝐨𝐮 𝐇𝐚𝐯𝐞 𝐀𝐧𝐲 𝐐𝐮𝐞𝐫𝐲 𝐎𝐫 𝐒𝐩𝐞𝐜𝐢𝐟𝐢𝐜 𝐑𝐞𝐪𝐮𝐢𝐫𝐞𝐦𝐞𝐧𝐭? 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐚𝐭𝐢𝐨𝐧 𝐨𝐟 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.persistencemarketresearch.com/request-customization/33512

Technology Trends Shaping the Surface Inspection Market

Technological innovation is at the heart of the surface inspection market’s evolution. Modern systems increasingly combine high-resolution cameras, advanced lighting techniques, and AI-driven analytics to deliver unparalleled inspection accuracy. Deep learning models are trained on massive datasets to recognize both known and unknown defect patterns, allowing systems to adapt to new products and materials without extensive reprogramming.

Another key trend is the shift toward inline and real-time inspection. Manufacturers are integrating inspection systems directly into production lines to detect defects as they occur rather than after production is complete. This approach minimizes waste, reduces downtime, and enhances overall equipment effectiveness (OEE). Additionally, cloud-based analytics and edge computing are enabling remote monitoring and predictive quality insights, further enhancing operational efficiency.

Regional Insights and Market Performance

North America remains the dominant region in the surface inspection market, supported by strong demand from automotive, aerospace, and semiconductor industries. The region benefits from early adoption of advanced manufacturing technologies, strict quality regulations, and government initiatives aimed at strengthening domestic manufacturing capabilities.

Asia Pacific, meanwhile, represents the fastest-growing regional market. Countries such as China, Japan, South Korea, and Taiwan are investing heavily in electronics manufacturing, semiconductor fabrication, and industrial automation. The widespread adoption of smart manufacturing practices and government-backed industrial modernization programs are accelerating surface inspection system deployments across the region.

Market Drivers Fueling Growth

The primary driver of the surface inspection market is the growing emphasis on automation and quality assurance in manufacturing. Rising labor costs and shortages of skilled inspection personnel are pushing manufacturers toward automated solutions that deliver consistent and objective results. Automated surface inspection systems significantly reduce human error while increasing throughput and inspection speed.

Another critical driver is the increasing complexity of manufactured components. As products become smaller, lighter, and more sophisticated, the margin for error narrows considerably. Advanced surface inspection systems enable manufacturers to detect micro-level defects that could otherwise compromise product performance, safety, or reliability.

Market Restraints and Challenges

Despite strong growth prospects, the surface inspection market faces certain challenges. High initial investment costs for advanced inspection systems can deter small and medium-sized enterprises from adoption. Integrating these systems into existing production lines may also require significant customization and technical expertise, adding to implementation costs.

Additionally, the effectiveness of AI-based inspection systems depends heavily on the availability of high-quality training data. In industries with limited historical defect data or highly customized products, developing accurate inspection models can be time-consuming and resource-intensive.

Emerging Opportunities in the Market

The expansion of the aerospace and defense industry presents a significant growth opportunity for surface inspection solution providers. With aerospace components subject to stringent safety regulations, manufacturers are increasingly investing in advanced inspection systems to ensure zero-defect production.

Another promising opportunity lies in the integration of surface inspection with digital twins and smart factory ecosystems. By combining inspection data with real-time production analytics, manufacturers can gain deeper insights into process inefficiencies, predict quality issues, and continuously optimize operations.

𝐁𝐮𝐲 𝐍𝐨𝐰 𝐭𝐡𝐞 𝐃𝐞𝐭𝐚𝐢𝐥𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.persistencemarketresearch.com/checkout/33512

Company Insights

Keyence Corporation

Cognex Corporation

Omron Corporation

Basler AG

Teledyne Technologies

SICK AG

ISRA Vision (Atlas Copco)

Recent Developments:

In 2024, leading inspection system providers expanded their AI-driven platforms to support sub-micron defect detection for advanced semiconductor nodes.

Several manufacturers introduced cloud-enabled surface inspection solutions to support remote monitoring and predictive quality analytics in smart factories.

Related Reports:

Automated Border Control Market

Pooja Gawai

Persistence Market Research

+1 646-878-6329

email us here

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.